Any business that distributes large quantities of non-digital products (anything made out of hard material) has to store its goods. Materials and final products are typically stocked in the warehouse and distributed to customers.

For anyone unfamiliar with the nature of the distribution business, a warehouse usually looks like a giant, dusty, and often disorganized facility with rows of ceiling-high racks stacked up with boxes and reminiscent of a labyrinth covered with signs of unknown meaning. Unfortunately, many warehouses look this way and function similarly, often resulting in shipment mismatch, delivery delays, and unhappy customers. Therefore, a business should have a well-developed set of policies and processes that ensure the smooth and effective operation of the warehouse facility to meet its objectives, which is the core of the Warehouse Management System to minimize or eliminate such problems.

Definition of Warehouse Management System

WMS is a software solution that helps companies monitor, manage, and optimize warehouse activity. Its sole purpose is simple: help employees run the warehouse facility efficiently by optimizing space utilization, resource usage, and material flow so all other areas of the business, including manufacturing and distributing processes, can run smoothly. In addition, it enables companies to coordinate many independent operations, maximize labor, get visibility into their entire inventory and even streamline how employees pick products and pack orders. In short, there is hardly any business that can get by without a WMS in today’s world.

Since the amount of data that needs to be stored, analyzed, and monitored is enormous, only some small businesses still rely on manual warehouse management. They still use pen and paper, so data is unsorted and probably unreliable. Warehouse management systems allow companies to control and administer warehouse operations and goods activity without wasting paper.

WMS uses database software to keep your warehouse data sorted and organized. Depending on business and manufacturing process complexity WMS includes different features that help you manage and supervise your warehouse. For example, basic WMS helps with location control and inventory management, while advanced WMS gathers and stores stock capacity information and tracks hours spent on particular tasks and activities.

A controlled WMS operates with nonwarehouse data, such as customers’ orders or transportation. As a result, it monitors activities outside of the warehouse and positively influences the workflow.

Some WMSs can be so complex that they become almost indistinguishable from WES (Warehouse Execution System). They integrate warehouse operations with inventory management and logistics operations.

Types of WMS

There are several types of warehouse management systems. All of them contribute to your business in different ways.

These are the most commonly used types of warehouse management systems. However, they can be changed or adapted by your business needs, market demands, or employee satisfaction.

- Standalone WMS uses the company’s existing network and is in charge of warehouse management. Typical features are receiving, picking, packaging, shipping, data and date tracking, and barcode scanning.

- Integrated WMS works as a part of ERP, so it covers more supply chain tasks. As a result, it costs more but helps you gain more control over the production process.

- On-premise WMS is the type you create yourself. However, it can cost a bit more because you will have to host and maintain the system’s hardware and software.

- The software provider hosts Cloud-based WMS on their remote server, which means that a provider is responsible for fixing bugs and issues and maintaining security.

How does WMS work?

The warehouse management system’s primary purpose is to monitor the warehouse activity. In other words, it overlooks the arrival, storage, and departure of materials and final products.

WMS uses different software and programs for monitoring, tracking, and analyzing the current condition of the warehouse and its activity. Using predefined processes allows businesses to gain more control over what is happening in the warehouse.

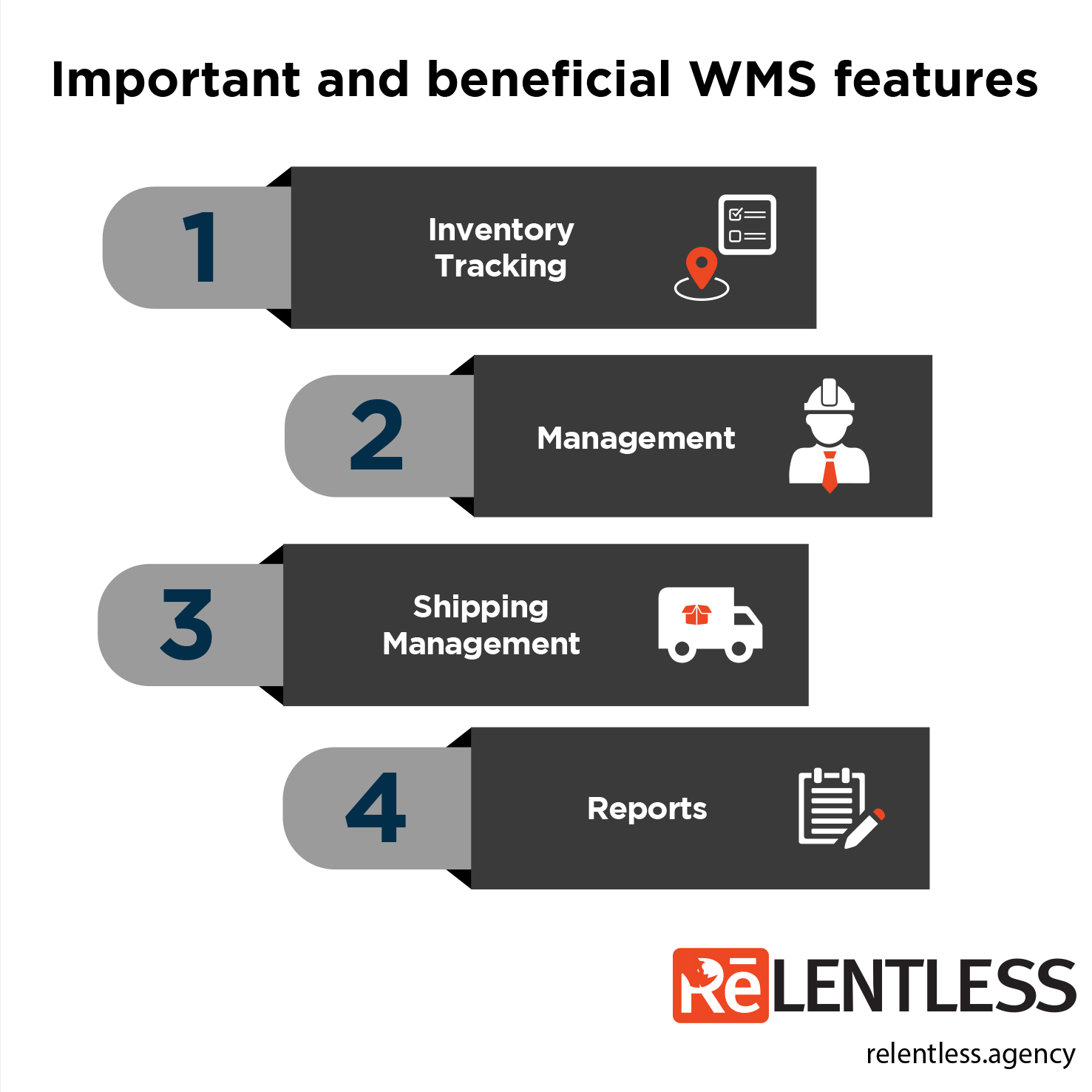

WMS features

There are several features that WMS brings along. All of them positively contribute to your business flow.

Inventory tracking

Investing in WMS helps you automate your process by adding barcodes, RFID, or AIDC. These systems will help you keep better track of your goods. They will also make the materials and products access easier.

Labor managing

WMS will help you in monitoring warehouse labor. As a result, you will get more insight into employees’ activity and will be able to direct it more effectively.

Shipping management

A warehouse management system will make shipping more straightforward and faster because the materials and products will be easier to find, reach, use and distribute. It will also inform you of any shipment delays and issues.

Reporting

Frequent reporting and report analysis can help you improve warehouse performance and upgrade your system and processes.

When these different steps of warehouse activity are operating without issues, the entire business can significantly improve and benefit.

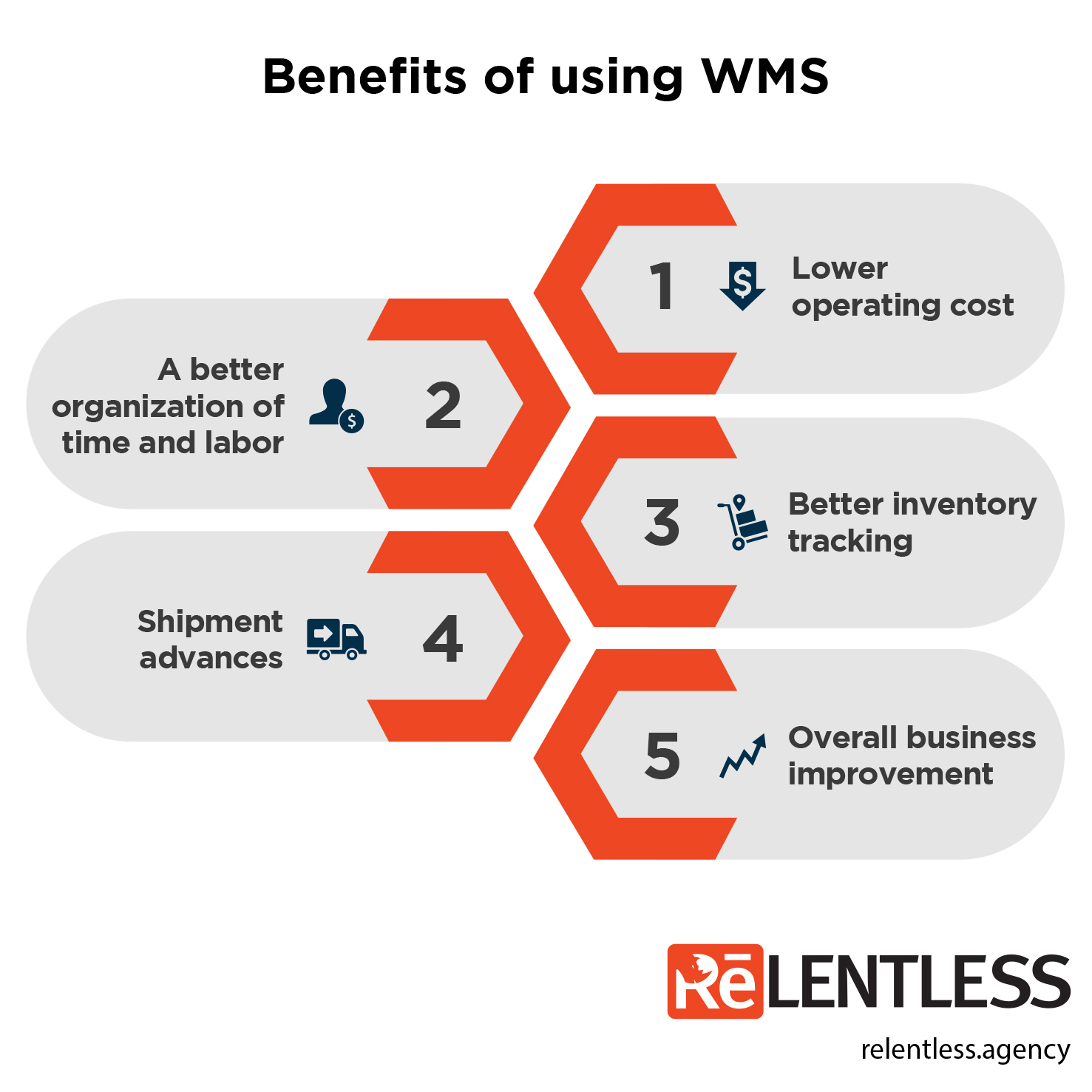

Benefits of using WMS

When analyzing the overall performance of warehouse and business processes, studies show that businesses using WMS enjoy many benefits.

Lower operating cost

With WMS, it will be much easier to reduce operating costs by optimizing all warehouse processes. Since WMS allows conclusion about warehouse floor space, You can place goods and materials orderly and easier to find. In addition, storage space is used correctly, so the performance of warehouse staff is increased.

Better organization of time and labor

WMS allows you to easily track and distribute all of your products and materials, saving workers time and energy.

Better inventory tracking

A warehouse management system will allow you to keep track of all materials and products automatically, so your company is aware of its goods at any given time. That allows more control over the production and shipment process.

Shipment advances

WMS allows more control over your inventory and more organization of goods, which makes shipment and further deployment of goods significantly easier and faster.

Overall business improvement

All previously stated improvements lead to a drastic improvement in performance, which leads to overall business success.

Implementing WMS to improve your business performance can prove one of the best decisions you can make. Not only will you save your employees time and energy, but you will also gain much more insight into the current state of your warehouse.

You will also gain much more control over the different business processes. By knowing them, you will be able to adapt your business to customer and market demands without losing profit. Consider hiring a team of experts to help you improve.